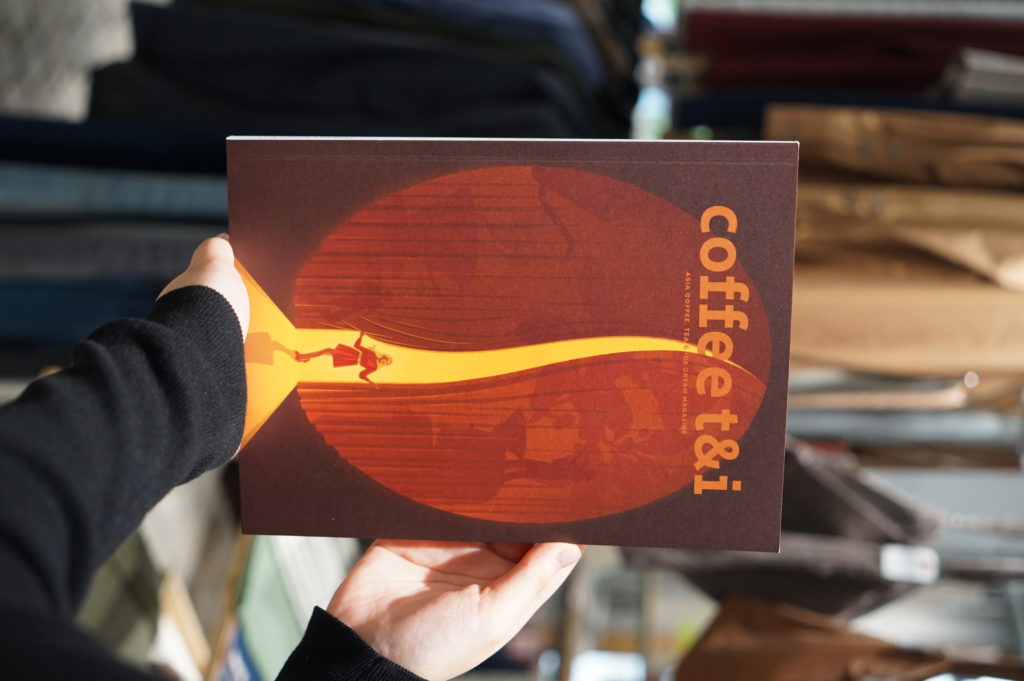

A consistent experience matters. Coffee consumers expect to be impressed from first sight to the last sip of their drinks. Suppliers and store managers are required to pay close attention to the packaging to ensure the coffee is well-kept from the date it is packed until it is served. To make this seamless experience attainable, effective packaging is absolutely necessary.

In today’s coffee market, convenience packaging is in vogue, and the worldwide trend shows no sign of slowing down. The packaging industry will do anything to meet its customers’ needs and keep up with their busy lives. Aspects such as smaller portion sizes that are easily portable are being taken into consideration regarding on-the-go packaging.

Before diving into the packaging patterns within the coffee industry, let’s first take a quick look at the science behind coffee packaging. As mentioned above, freshness is challenging yet crucial to coffee beans as they are vulnerable to exposure of sunlight and air. One of the big enemies is oxygen. With its infiltration, roasted and ground coffee would become stale and lose its flavour. This process is called the oxidation reaction, and it results in the reduction of aroma and shelf life, ultimately leading to the deterioration of coffee quality. Another impeding factor that coffee packagers should be concerned with is carbon dioxide (CO2). Once coffee beans are roasted, they will continue to release CO2 which will eventually cause the package to expand if it is completely sealed, and in some cases even rupture. Clearly, with only the proper packaging are we able to experience the freshest and fullest-flavoured coffee.

The most effective packaging should be equally as attractive as it is functional. So, how are members of the coffee industry translating the needs of their brand, as well as of their customers, into concrete innovations?

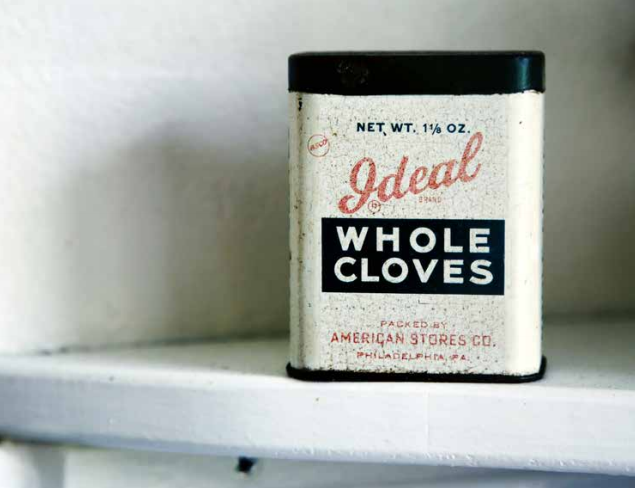

Coffee in cans

Coffee in a can is not a new practice; it is an old yet predominant packaging method in the coffee world. With regards to this type of airtight packaging, there are two pioneering technologies that we will discuss. The first one is Hills Brothers Coffee that started a packaging revolution in coffee industry in the early 1900s; the well-known “vacuum packaging” technique of removing air from packs led to better preserved coffee beans. In 1906, the Hills Brothers introduced their coffee can by applying the vacuum process, with a design of the “coffee taster” that was inspired by coffee’s origins in Ethiopia. This eventually became the company’s trademark. It was not until 1914 that they began using the Red Can Brand. It is an iconic one pound vacuum coffee can that is opened with a metal key, and the brand is still known for it today. However, the vacuum packaging method is not perfect. In a circumstance where freshly roasted coffee beans are to be transported and the degassing process is uncompleted, the gas can impact coffee flavours negatively.

Illy caffè takes the lead in another way. They utilize pressurized packaging for canning their coffee beans immediately after roasting and ensure freshness until the can is opened. With this patented technology, Illy has been capable of introducing their canned ground coffee to modern homes since 1962. Moreover, it has become the first Italian coffee roaster to bring their espresso coffee in cans across the ocean to the United States while maintaining its aroma and flavour.

So, how does the pressurization process work? After the coffee is freshly roasted, Illy puts the beans or ground coffee in recyclable cans and pressurizes each one using inert nitrogen. Imagine how fine wine is matured in bottles, this process allows the aroma to stay and the flavour to develop in a pressurized environment. The technique results in a ground coffee which can be kept longer than in any other packaging. In 2001, Illy brought their signature 8.8oz can to the world. These recognizable slim brushed metallic tins use the colours of red, green, and black to represent different coffee categories, and the company even invited artists to design their specific 250-gram icon.

Generally, cans are excellent packaging for coffee. Not only do they keep oxygen and light out, preventing the beans from being negatively impacted by the environment and prolonging freshness, but they can also be reused or recycled. It is perhaps due to these benefits that canned packaging has had somewhat of a renaissance lately and it is extending to the specialty coffee market.

Capsules or K-cups?

Single-serve coffee machines been increasing in popularity due to their efficiency, user friendliness, and professional experience. When it comes to the pod containers that the machines hold, they usually come in the form of a capsule and K-cup packaging. Currently, there are two brands that are dominating these two packaging patterns, Nespresso by Nestlé and Keurig by Keurig Dr Pepper.

The K-cup term is trademarked by Keurig Green Mountain, the precursor of Keurig Dr Pepper. These K-Cups are easily recognizable for their ringed design on a plastic body, an aluminum lid, and a paper filter. Each cup is nitrogen-sealed to protect the coffee’s delicacy. The Keurig system functions by piercing the aluminum top with its patented spray nozzle and allowing water to penetrate the filter inside the cup which contains the coffee grounds. Nespresso has developed an exclusive packaging approach that seals its coffee tightly in an aluminum foil capsule. Working in a way similar to Keurig, the water is pumped through a series of multiple perforations in the Nespresso capsule and ultimately delivers a hot beverage characterized by the signature crema on top.

It seems Keurig and Nespresso are of equal strength when it comes to machinery and outcome, but if we take a closer look at the packaging and design, we will ultimately find some key differences between them. Firstly, capsules made of aluminum foil can be more capable of retaining the fresh and full flavour of ground coffee compared to those made of plastic, since they have better airtightness. Second, the aluminum foil capsules bear a more aesthetic variety of decoration including shiny colours and patterns, which can make the coffee pods more eye-catching and visually appealing. In addition, in some cases plastic cups might not be suitable for high temperatures as harmful chemical elements could be generated. Finally, in terms of sustainability, aluminum is a recyclable material, though it can produce waste if it is not disposed of appropriately. That being said, plastic capsules are essentially non-recyclable. Even in areas where they can be recycled, the cups can only be recycled by manually breaking apart their components, and they are more often filtered out because of their small size. This negative impact on environment also became the primary criticism of the Keurig brand, and even the inventor of the K-cup said that he felt bad for its lack of sustainability. Hence, it seems as though Nespresso capsules have a more optimistic future given the growing awareness for environmental protection.

Drip coffee in bags

The drip coffee bag was born in Japan and has since become a standard in the area of single serve coffee around the globe. The coffee bag went through several variations, but it was not until 2001 that the bag was patented by UCC Ueshima Coffee and grew into its most common form that we see today.

The first version of drip coffee bag was invented in 1990 by Yamanaka & Co. It adopted a non-woven fabric comprised of a microfine fiber. The upper part of the bag could be easily torn by fingers, and it was designed with ears to be held in a cup. This was the prototype of drip coffee bags in their early phase. However, there was one downfall: the bag can only hang on one side of a cup meaning it was not stable enough to be used.

In 1999, OHKI improved the drip bag by adding hooking components on both outside surfaces of the bag. Made of a thin plate material, the hooking unit is made of an edge and an arm (ear) together with a tongue inside which can be pulled up from the main body. In this way, the bag was able to sit on any cup steadily. Packaging of this style was very close to the pattern we use now.

When UCC brought the product on to the market, it further simplified the bag by combining the arm and tongue into one part. Now, the present design provides a drip coffee bag that can be readily set on a cup or mug of nearly any type while keeping a stable shape. Customers now have the ability to make their own coffee casually and with ease by simply opening the top, hanging the drip bag on a mug, and pouring hot water through the coffee grounds. It is possible to craft a delicious coffee as if you were a barista.

Packaging for RTD coffee

Due to our modern fast-paced lifestyle, ready-todrink (RTD) coffee of the instant nature is growing in the highly trend-driven market. Likewise, to make an impact on modern-day consumers, an eye-catching and aesthetically pleasing look is just as important as the technologies used in packaging. We can find a number of innovations in demand, like iced coffee, packaged cold brew, and liquid (or frozen) coffee concentrates. These beverages are available in several packaging formats.

According to market research, the most popular packaging designs employed in the RTD coffee market are cans, glass bottles, and PET bottle packaging. Led by UCC Ueshima who pioneered canned coffee with milk in 1969 and established the basis for today’s canned coffee market, pop-top cans have become a prominent option.

While conventional coffee is often sold in cans, a number of brands have entered the cold brew packaging sector in the last five years, and the category still has room to grow. On top of that, many gourmet coffee brands tend to try classy packaging such as pouches, bags, and boxes with unique shapes, all of which belong to the category of flexible packaging. It is also worth noting that RTD coffee in 200ml and 250ml portion sizes is really growing in popularity.

The market of RTD coffee is expected to grow at a 4.5% compound annual growth rate during the next five years, and even more packaging formats are projected for the future.

Future of coffee packaging

It still remains as a challenge for brand owners to balance environmental concerns and a need to package coffee which not only delivers an appeal to quality but also satisfies consumers’ needs with their busy lifestyles. This is perhaps why we are always talking about the significance of sustainability, but it should not be considered as just a “trend” anymore; it is a necessity for coffee packaging management. The balance between convenience and sustainability should not be a dilemma for coffee brands. Rather, they are two sides of the same coin.

NO COMMENT