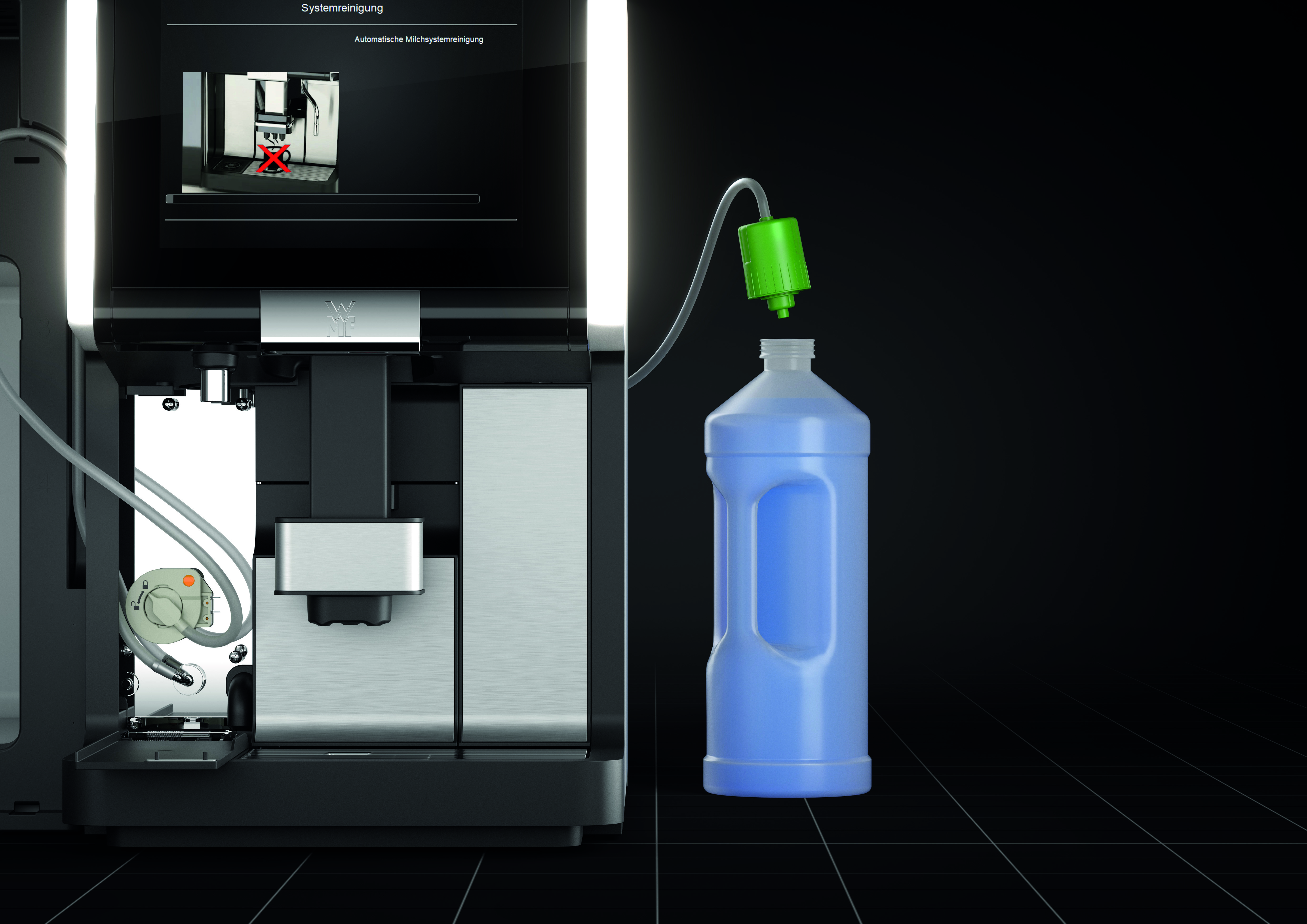

The most important characteristics of a WMF coffee machine include premium beverage quality, process reliability and performance. In order to ensure that these success factors are reflected not only in the operation of the machine, but also in its cleaning processes, WMF Professional Coffee Machines is launching “WMF AutoClean”—the industry’s first fully automatic solution for cleaning. Both the coffee system and milk system are cleaned in accordance with HACCP requirements without any external assistance. All of the time-consuming, error-prone cleaning tasks previously performed by the user are eliminated completely and the input required from them is reduced to an absolute minimum. An integrated timer can be used to specify exactly when and at what intervals the AutoClean system should start work—everything else is taken care of by the machine. State-of-the-art components guarantee automatic feeding, dispensing and monitoring of the cleaning agent. By the time the first staff member arrives at work, the machine will already have started up, cleaned itself and be ready to go. And AutoClean deals with all the necessary tasks after work as well. Crucially, this impressive functional range does not mean having to sacrifice a compact design. All components of the new system fit perfectly into the existing machine housing. As a result, the machine seamlessly combines maximum functionality with perfect elegance, epitomising the WMF brand message “Designed to Perform”. AutoClean will be available for the WMF 5000 S+ from June 2021 onwards and another series will be added by the end of the year.

Wherever coffee machines are used—from cafés and restaurants to petrol station shops or office kitchens—they require regular and thorough cleaning. Unfortunately for the staff, this means they have to carry out daily cleaning processes before or after their actual working hours. Not only does this take extra time and effort, it is also a potential source of errors which could damage the machine or even lead to hygiene violations. For this reason, WMF Professional Coffee Machines has developed a cleaning system that offers exceptional efficiency and process reliability. Thanks to a level of automation that is unparalleled across the industry, WMF AutoClean cleans the entire milk and coffee system fully automatically.

Automated reliability

The new technology offers clear advantages for coffee machine operators. Rather than having to ask employees to carry out additional tasks or even paying external service staff to deal with daily cleaning, WMF customers can rely entirely on their machines. All they have to do is set a start time for daily system cleaning in the machine’s internal timer—for example, in the evening after closing time. Thanks to its innovative time management, the AutoClean system can then take care of everything by itself—punctually, efficiently and reliably. The only input required from a staff member is a single intervention when cleaning the milk system—but this can easily be done while filling the milk container.

Reliability is also crucial when it comes to dispensing and using the cleaning agents correctly. If a staff member adds the wrong product or dispenses the wrong quantity, this could result in serious violations of hygiene regulations. As the AutoClean system can only be used with a special WMF cleaning system comprising granulate and fluid, it eliminates this risk and dispenses the components sustainably and fully automatically. This ensures extremely hygienic, HACCP-compliant operation at all times. The two cleaning components have to be refilled after 60 and 40 cleaning cycles respectively.

Time- and space-saving technology

The innovative AutoClean technology has a direct impact on the efficiency and cost-effective operation of the machines. Although it makes little difference to the duration of the actual cleaning process itself, the time-consuming preparation and follow-up tasks are completely eliminated. There is no need for staff to add a suitable cleaning agent, connect the container or remove and refit the spout. This saves around five minutes per machine per day—for facility management teams with ten machines to look after in one building, that is around an hour of working time that can be put to use elsewhere. Furthermore, new staff members no longer need to be trained to carry out cleaning processes.

NO COMMENT